What Number Crunching Did in New Zealand

A background as an agricultural economist has enabled one New Zealander to build one of the most efficient dairies in his region.Managing inputs is a challenge but it allows Foster Kalma to have a robust system throughout the highs and lows or weather and prices.

His 115 hectare holding at Waitoa, on New Zealand's northern island, supports 635 jersey cows on a split calving operation seeing 500 spring calve.

As a system five farm, imported feed makes up just over 50 per cent of the cows’ diets year round.

For the last six years, a leased support block has provided 48ha maize silage (1000t) and 100t grass silage, plus 750t palm kernel expeller (PKE) is also fed during the year.

During lactation, the cows are fed 16kg DM/cow/day, including pasture. Three hundred cows are also wintered on the support block for six weeks.

Foster says fluctuations, particularly profit, are greater with high input systems and require focus on every detail. So where last season’s high payout benefited the farm with an income increase, this year Foster will have his eye on feed costs during the reduced payout.

"One of the big risks for me is relying on the 1000 tonne plus of maize from the runoff. In the last two years we have had a poor harvest, due to weed problems, drought and a new planting system," says Foster.

“Preparing that crop is critical to my system, but more so in a low payout year.”

Foster says a plus of his system is flexibility to manage through dry off, carry over, cull or stock purchases in different seasons.

“If milking cows are leaving too much feed, the dries can follow. With the lower payout, we cull more heavily and earlier to get rid of old, empty, low production or mastitis-prone cows,” says Foster. “The 30 cows I’ve removed already means a feed reduction of 15 tonne per month.

“Right now (September), the milkers get 8kg grass, 4kg maize and 4kg PKE. We keep increasing the pasture as the spring flush hits. We base our pasture decisions on leaf emergence, which determines rotation speed and maximises growth by grazing at the 2.5-3 leaf stage.”

The rotation will speed up from a 25 day round to 21 days and, in an exceptional year, may provide a small amount of silage. “In the last two years, our nitrogen (N) fert has decreased from 250 to 50kg N/ha/yr. Instead, effluent is applied to recently grazed paddocks.”

Reducing Extra Costs

The more expensive feed will be cut down this year, to ensure grass is well utilised. This means cottonseed – a protein source for calving cows – may be cut back for the autumn herd calving in February.

“At around $700 per tonne it’s very expensive, so we may only use a small amount for newly-calved cows and find a cheaper option.”

Last year Foster fed 240t DDG (dried distillers grain), kibbled maize, cottonseed and soyhulls to lift production, due to the poor maize harvests. It’ll only be fed to early calving cows this year.

During last year’s high payout, Foster carried feed over from the previous year (2012/13) and purchased an extra $200,000 of feed – helping lift production 10 per cent and providing additional feed this season.

Foster checks PKE prices monthly and contracts around 200t three times a year. Delivered PKE under $300/t is contracted – otherwise smaller amounts are secured to ensure supply.

Contracts in place mean no chasing feed mid-drought. One thing won’t be cut in a tight season though – his team of five.

“We have 128 cows per full-time equivalent, that’s a lot of staff for our farm size, but reducing it is not an option. Two have been with me for 14 years and we’ve created a good system together. Plus, we have staff for time off and their days aren’t excessively long.”

Advice and Information is Key

Foster says good advice helps with key decisions and his consultant, Bill Rys, identifies mistakes and provides comparisons with other farms.

"Bill has helped balance the feeding and stocking rate, and ensure we fully utilise homegrown and imported feed," says Foster. "I have seen a lot of high input systems where extra feed is put in and the milk solids don’t come out the end. The feed replaces grass and grass is wasted.”

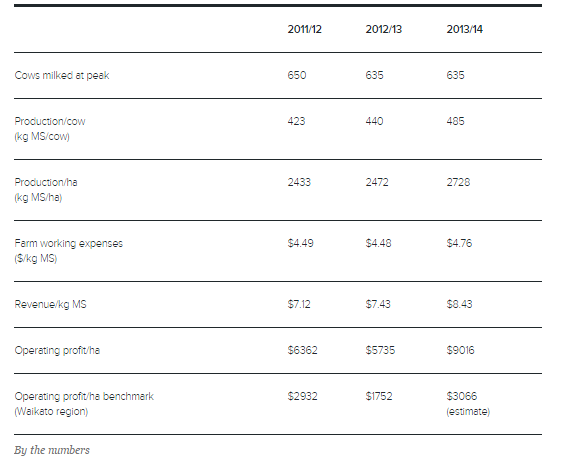

Benchmarking against other farms has provided gains.

"Benchmarking helps identify the farm’s strengths and weaknesses, by analysing your numbers. I've used Red Sky and DairyBase for financial analysis and enter Dairy Business of the Year to compare myself against others."

The Kalma farm has previously fared well in the competition – having won the Australasian title in 2010 and the 2013 ‘environmental high input’ title and ‘best high input system’ awards.

System Efficiency

"For me, it’s about creating a system that works well. I tend to work on a five-year basis for making decisions. I’m running good cashflow systems and do spend quite a bit on repairs and maintenance, rather than capital investment," says Foster.

Because half the diet is supplement, Foster also has less concern about drought.

"The whole aim is to get through to March, when the maize silage comes off, then we’re pretty right for another year."

November 2014