Ethiopian Dairy Focus: Protecting Farmers and Consumers

An efficient milk supply chain is particularly challenging to manage in Ethiopia, where religious fasting and corruption interrupts demand and processing.One of the many challenges smallholder dairy farmers in Ethiopia face is securing a dependable market for fluid milk, especially during religious fasting periods of the Orthodox Church.

This is according to the Livestock and Irrigation Value Chain for Ethiopian Small Holders (LIVES) who have followed a entrepreneurial local on a steady path to expansion through milk.

Many believe that to overcome such problem, large milk processing plants serving many consumers in urban areas are essential, write the team at LIVES.

Very few people will risk establishing smaller capacity milk processing plants in small towns where the market for processed dairy products is untried.

Recognizing such fluctuating market demands,Tsehaye Reta installed a small milk processing plant at the foot of the historic Mount Soloda in Adwa district, Tigray region.

Tsehaye addressed smallholder dairy farmers’ market problem through a simplified concept of ‘value chain’ whereby farmers supply their fluid milk to his plant, and supermarkets, retailers and consumers in turn buy pasteurized milk and other processed dairy products from him.

The road to realize this was neither smooth nor short. He suffered under the previous Derg regime, receiving two capital punishments. Tsehaye, however, never gave in and he joined the Tigray Peoples Libration Front.

Before and after the fall of the Derg, Tsehaye equipped himself with knowledge and skills through formal training and hands on experiences. His renewed stamina helped him start a private small-scale agro-processing business, including small capacity milk, tomato paste and fruit juice processing plants in Adwa.

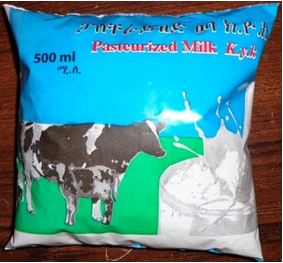

The small milk processing plant started with 9 Holstein cows (6 purchased and 3 donated), a 500-liter capacity pasteurizer and a mini milk packaging plant.

Although the demand for fluid milk varies, with the current capacity of the plant, he can collect milk from 100 smallholder dairy farmers.

The habit of consuming pasteurized milk is just being popularized to consumers in Tigray through supermarkets, cafés, and hotels, and with more exposure to the consumption of pasteurized milk, he will expand his fluid milk collection to a radius of 40 km and reach more dairy farmers.

Tsehaye’s 500 ml pasteurized milk is labeled ‘K.Y.K’ and sells for 8 Birr, 60 per cent less than a similar product transported from Addis Ababa. The small milk processing plant is also helping many smallholder dairy farmers during fasting periods by purchasing large volumes of fluid milk for butter making with improved shelf life.

An interesting part of this butter making business is the close link created with poor women retailers who sell the butter in small pieces to beauty salon owners and individual consumers as a hair butter cream. The processing plant also produces cream, plain yoghurt, and cheese whenever demanded by consumers.

Tsehaye’s aim is to develop a streamlined processed dairy products supply line to the growing population in Tigray and elsewhere. He will also soon upgrade from his current pasteurizer to another with 1000 liters capacity and a faster heating and cooling time, and introduce on time delivery of pasteurized milk and other milk products in trucks equipped with cooling facilities.

The small scale processing of milk into different products as currently being done by Tsehaye Reta can enormously help smallholder farmers get more reliable markets throughout the year and protect the safety of consumers in small towns. The expansion of such smaller capacity milk processing plants is also one means to realize more inclusive dairy value chain development.

Such initiatives need to be supported by strong sense of solidarity, collaboration, and effective marketing strategy development.As successful dairy value chain demands strong collaboration along all stages of the chain, the LIVES project works closely with Tsehaye and his milk supplying farmers to link processed milk products to consumers in Aksum University, Almeda Textile Factory, Saba Stones Factory, Hospitals, Schools, and other wholesalers in Mekelle.