Calculating Carcass Yield: Use Dressing Percentages

Instead of thinking simply about yield of finished animals, the team at Certified Angus Beef (CAB) are advising to analyse dressing percentage.Cattle feeders live by numbers, says CAB. Gain, feed efficiency, rations and of course prices—each one matters to the ultimate bottom line, but there’s one figure that may be less understood among cow-calf producers.

“If you spend much time talking with a feedlot manager about components of profitable cattle, it won’t be long until he or she starts talking about dressing percent,” says Mark McCully, Certified Angus Beef LLC (CAB) vice president.

It’s often referred to simply as “yield” though it’s not at all the same as Yield Grade.

“Dressing percentage is simply the percent of a live, finished steer or heifer that ends up in the carcass form,” he says.

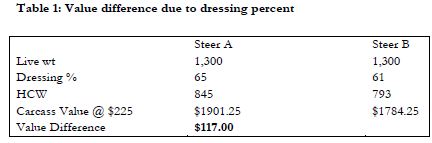

The math is pretty straightforward. McCully shares this example: if a 1,300-pound (lb.) live steer produces an 819-lb. hot carcass, that number divided by the live weight equals .63 or 63 per cent. A bigger number, or higher yield in this case, is more favorable.

With a typical range in dressing percentage falling between 57 per cent and 67 per cent, what impact does a shift one way or the other have on profit?

“When you put a pencil to it and figure in today’s relatively high prices, those points really add up,” McCully says.

Selling that 1,300-lb. steer at a carcass-weight price of $225 per hundredweight (cwt.) brings up a $117 difference when moving from a dressing percent of 61 per cent to 65 per cent (see Table 1).

Producers used to think of dressing percentage as a packer calculation, but as more cattlemen move to selling on a grid, it figures into the pricing formula.

“If you have cattle that dress higher, then you have a higher percentage of their total live weight that you’re getting paid for and you’ll get more value,” says Amy Radunz, University of Wisconsin animal scientist.

Carcass weight is the basis for payment, then quality premiums and discounts are added, and many grids also incentivize above-average dressing percentage.

“Beating that plant average puts more dollars in the producer’s pocket,” McCully says.

Dressing percentage does impact cash sellers, too.

“If you are going to market cattle on a live basis, dressing percentage is a factor because the packer-buyer is going to take that into account as he gives you a live price,” Radunz says. “They don’t want to pay for weight that has less value to it.”

“Buyers are sitting there in the auction barn essentially putting those cattle on a grid,” she says.

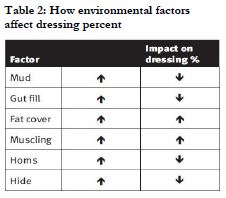

As they drive the yard or evaluate cattle in the ring, packers are looking at all the factors that affect dressing percentage: horns, amount of hide (Brahman influence), mud, gut fill, fat cover and muscling (see Table 2).

“As cattle get fatter, dressing percentage goes up,” McCully says. “Of course overly fat is not the goal, but genetics and days on feed come into play.”

Especially when the carcass price is high enough and feed prices are low enough, feeders may keep cattle on feed longer to improve dressing percentage.

“I’m putting on more carcass weight and at the end of the day, pounds are a large portion of the value of that animal,” Radunz says. “Plus there are premiums for marbling and it insures that regardless of genetics they’re going to have the potential for more to hit the upper two-thirds of Choice and maybe even Prime.”

“A Holstein animal, for example, has a higher percentage of head, feet and legs, especially because they are so lightly muscled,” she says, noting that ranchers can potentially improve dressing percentage by paying attention to the ribeye area (REA) expected progeny difference (EPD), an indicator of muscling.

“You want to make sure you’re selecting for cattle that have the combination of Quality and Yield Grade, those cattle that will marble but also have muscling,” Radunz says.

McCully says using all available selection tools should help cattlemen please both feeders and consumers: “When you know what your customers need, you can design a product that will keep them coming back for more.”