How Profitable are Silage Inoculants?

Silage is the product of the fermentation of different crops caused mainly by lactic acid bacteria (LAB) based on the acidification of the material under anaerobic conditions, writes costa Aragón, Y. PhD, Technical manager, BIOMIN Holding GmbH.Introduction

Biological silage additives are used in two main directions:

- to enhance the fermentation (homofermentative LAB producing mainly lactic acid) = stimulants; and

- to lengthen the aerobic stability of the silage in the feed out phase (under exposure to air, heterofermentative bacteria producing acetic or propionic acid) = inhibitors.

But in terms of profitability, are silage inoculants really interesting for the producer? How can we measure their profitability? The following calculations are based on the improvement of the energy content in silage compared with non-treated silage.

Economical calculations:

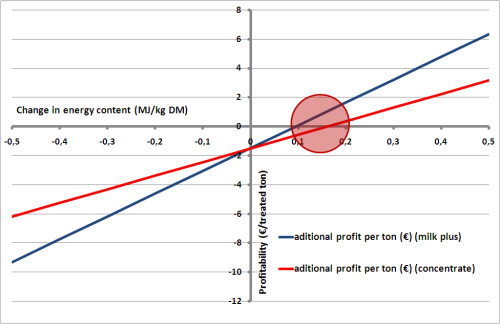

In Figure 1 the possible profit obtained with different energy contents compared with non treated silage is shown. The profit is calculated from a higher production of milk or from the savings in concentrate. The functions become positive (profitability) when the difference between the energy content in treated silage and non-treated silage exceeds around 0.1 MJ/ kg DM. It is also noticeable that an energy loss for a lower energy content than this value (0.1 MJ/ kg DM) would cause financial losses (at the prices for the calculation) of about 3.80 – 5.20 €/ ton silage when the energy content decrease from 0.0 to - 0.1 MJ/ kg DM. Silage inoculants with high efficacy influence the silage process and aerobic stability. Their success in farms is supported by the main improvements in the silage:

- better fermentation,

- longer aerobic stability,

- higher DM and energy recovery and

- cheaper compared with acids

In Figure 1, a sensitivity analysis was performed taking into account the energy losses/ wins in silages treated with silage inoculants. For the calculations the current market prices were used.

The functions become positive (profitability) when the difference between the energy content in treated silage and non treated silage exceeds around 0.1 MJ/ kg DM. It is also noticeable that an energy loss for a lower energy content than this value (0.1 MJ/ kg DM) would cause financial losses (at the prices for the calculation) of about 3.80 – 5.20 €/ ton silage when the energy content decrease from 0.0 to - 0.1 MJ/ kg DM.

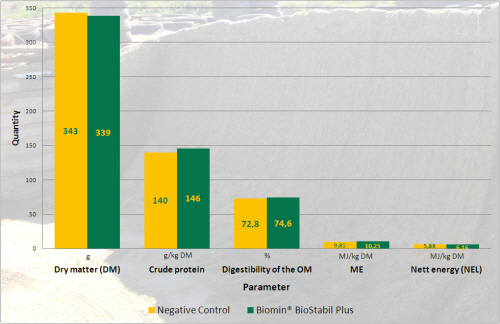

In order to illustrate the above calculations, a trial was selected as case study. Parameters of a field trial (120 TM) conducted in Lower Austria, Austria, with grass silage 1. cut are shown in Figure 2.

The DM as well as the Crude protein do not differ markedly between the non treated silage and the silage treated with the inoculant. However, the digestibility and the energy content (ME and NEL) were improved by the use of the silage inoculant (+ 1.8 per cent, + 0.4 and + 0.28 MJ/ kg DM respectively). Based on the higher energy recovery, the profitability in the use of the silage inoculant was calculated.

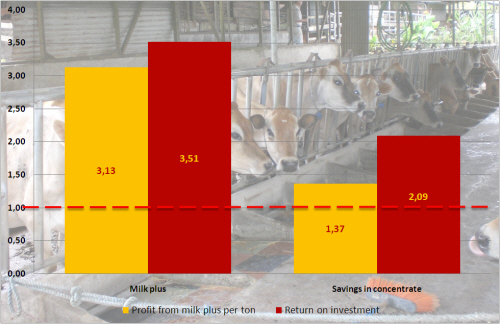

In Figure 3 the profit per ton and the Return on Investment (ROI) are presented. The profit per ton reaches from € 1.37 to 3.13 depending on the parameters taken into account (savings in concentrate or extra milk production).

The ROI also shows that the investment in silage inoculant pays off. The ROI is higher for the extra milk production (3.51) than that for savings in concentrate (2.09), both clearly over the financially worthwhile limit (1).

Similarly to the calculation performed for milk production, an estimation of the profit per ton and ROI was made for meat production with an average value of energy requirement between 150 to 650 kg body weight (BW). The profit per ton silage in the meat production was of € 4.17 and a ROI of 4.33.

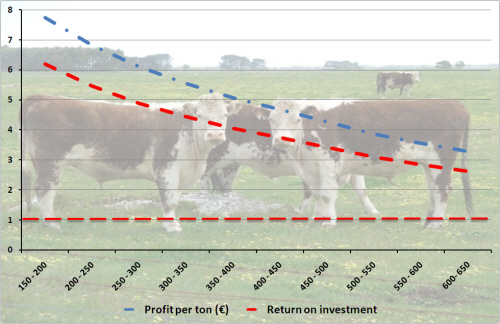

However, the efficiency in the use of the energy in feed decreases with increasing body weight. Is it profitable to use silage inoculants for heavier less efficient energy converting animals? The answer can be seen in Figure 4. As shown, the profit per ton decreases with decreasing energy efficiency from about € 8.00/ ton (150 kg BW) however never under € 3.00 €/ ton (650 kg BW). The same trend follows the ROI, from over 6.00 to approx. 2.5 from 150 to 650 kg BW.

Conclusions

The use of an additive should always be associated with good management practices. Following these management practices will improve ensiling and increase the effectiveness of an additive. The effectiveness of the use of a silage inoculant is dependent on the market situation, prices, conditions in the farm, etc. These calculations are an orientation in order to help producers in the decision to use silage inoculants, or in order to estimate the potential profit.

June 2009